The largest sources of copper are based on porphyry copper deposits. Although these deposits can be found at many places around the globe, the greatest concentration of the largest copper porphyry deposits is located in the northern part of Chile.

The deposits are formed by hydrothermal fluids which originate from voluminous magma chambers below the deposit itself which consists of disseminated ore minerals in hairline fractures and veins. Deposits with Copper concentrations starting from 0,15% may be of economic value; by products such as Molybdenum, Silver or Gold may be found as well.

In 2021 our team performed a series of blasthole measurements in Copper mines located in North Chile which demonstrate the capabilities of the IBERIA XRF device. This report summarizes the procedures carried out, the results obtained, and the implications of these results for IBERIA measurement campaigns.

Our technology partner J&C Bachmann currently offers two versions of the IBERIA XRF probe, IBERIA 53 and IBERIA 70. The numbers refer to the probe diameter; the probe used depends on the diameter of the hole to be measured as well as the target elements. Due to the large diameter an IBERIA 70 probe is utilized in most blasthole applications. Performing a measurement, the probes are connected to a Mount Sopris winch and a power source, switched on, and slowly lowered into the hole. A depth encoder records the depth of the probe based on the lowering of the winch cable. The measurement time for each elemental analysis data point is typically set to 10 seconds, and the probe velocity varied between 0.5 and 1.3 meters per minute; so each point therefore corresponds to a depth range of 100 to 250 mm. For analysis of the results, multiple runs in the same hole were compared. A weighted average copper grade was calculated and compared to a laboratory measurement of the blasthole debris composition.

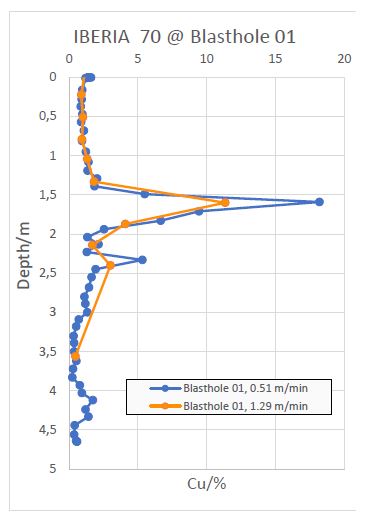

Copper grades of samples analyzed in the laboratory were available for all measured blastholes. So the IBERIA 70 XRF probe could be used to measure copper concentrations within three blastholes with depths up to 5 meters and to compare the results with the laboratory analyses. The results of the uphole and downhole measurements in blasthole 01 are shown in Figure 3. It can be clearly seen that the log taken with a speed of only 0,51 m/min

shows a far better resolution than the log taken with more than twice of this speed. This leads to the supposed procedure to take a quick log on the way down; based on these results the speed can be reduced in areas of interest when the probe is moving up afterwards.

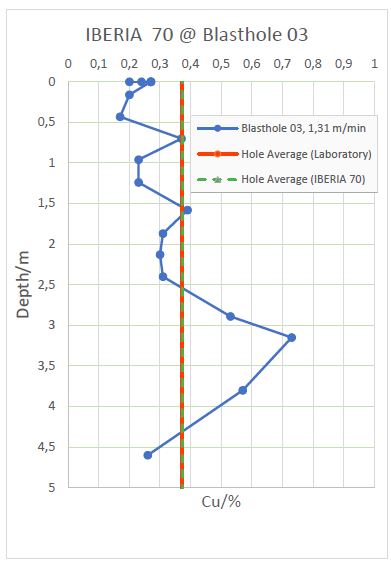

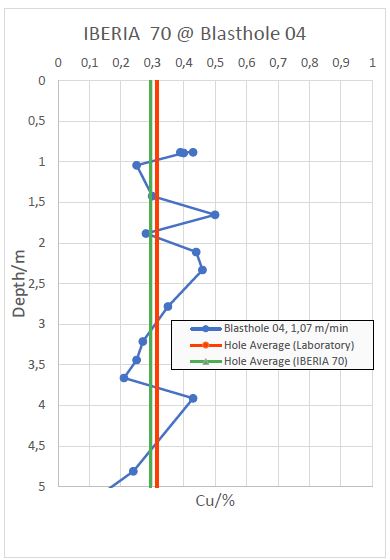

As already mentioned, highly concentrated layers of copper ore were identified in blasthole 1 at depths of 1.6 and 2.3 meters. The presence of these layers was confirmed by a replicate downhole measurement. In blastholes 3 and 4, the IBERIA 70 probe identified smooth variations in copper concentration, with no copper

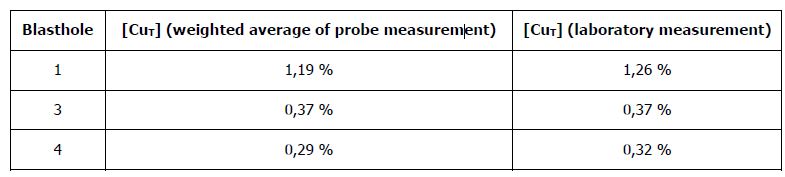

grades higher than 1.4% detected. Table 1 shows the accuracy of all blasthole XRF measurements. A weighted average was calculated from the series of measurements in each blasthole and compared to a laboratory measurement of the blasthole debris. In each case, the relative measurement error was less than 10%.

Weighted average copper grades determined by the XRF probe compared to the laboratory analysis results.

The results of the IBERIA XRF probe show that this technique is highly effective for measurement of ore grades in

blastholes, and the results can be obtained at high spatial resolutions and a turnaround time of minute s rather than

days to weeks, eliminating the time critical logistics of the sample transport. The accuracy of the measurement is

very high. In all blastholes the XRF probe was able to match the average Cu concentration. The blastholes showed

a max. deviation of 6% relative compared to the laboratory analyses which were a composite of the whole blasthole.

As shown by the uphole and downhole replicates of the blasthole measurements, these measurements also have a

high reproducibility, with the differences in the measured copper grades in replicate measurements primarily due

to differences in probe velocity and the associated spatial resolution.

An additional important factor in the blasthole measurements is the high spatial variation of copper concentrations

within the blasthole. This is typical in copper porphyry deposits, where highly concentrated regions of copper ore are surrounded by low grade rock. Depending on the speed of the measurement and therefore the wall area included in one data point, the indica ted grade will vary. As the measurements are obtained using a mobile probe,

the movements of which tend to have an averaging effect, the density and grade of the highly concentrated regions can be viewed as a proxy for the overall copper concentration with in a region wide enough to potentially be extracted.

Porphyry copper shown on core samples from similar holes of the deposit

These measurements demonstrate that the IBERIA probes measure effectively and accurately blasthole copper

concentrations. Furthermore these measurements show a high reproducibility in repeated measurements and an

excellent correlation with the grab sample of the drilling debris.

The performed measurements show that with a speed of around 1 m/min a good compromise of resolution and measurement time can be achieved. This translates to a measurement time of 6 minutes per hole. The experience in the field shows that the repositioning of the tripod for adjacent holes can be done within 2-3 minutes, which leads to a time of around 10 minutes per blasthole in an active mining environment. Considering that the downhole measurement can usually be performed while new blastholes are drilled, the time impact of the IBERIA grade measurement on the mining process is negligible.

The cost efficiancy are not only less laboratory cost but also a higher efficiency in the upstream process, resulting in

• Optimization of blending conformity before processing plant

• Decrease of waste / dilution

• Increase of processable ore / process efficiency

IBERIA enables the user to gain ore grade data in real time, with high accuracy. The data can be used to optimize the resource model, optimize the blast sequences, and will allow to adjust your upstream processes.

Figure

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |