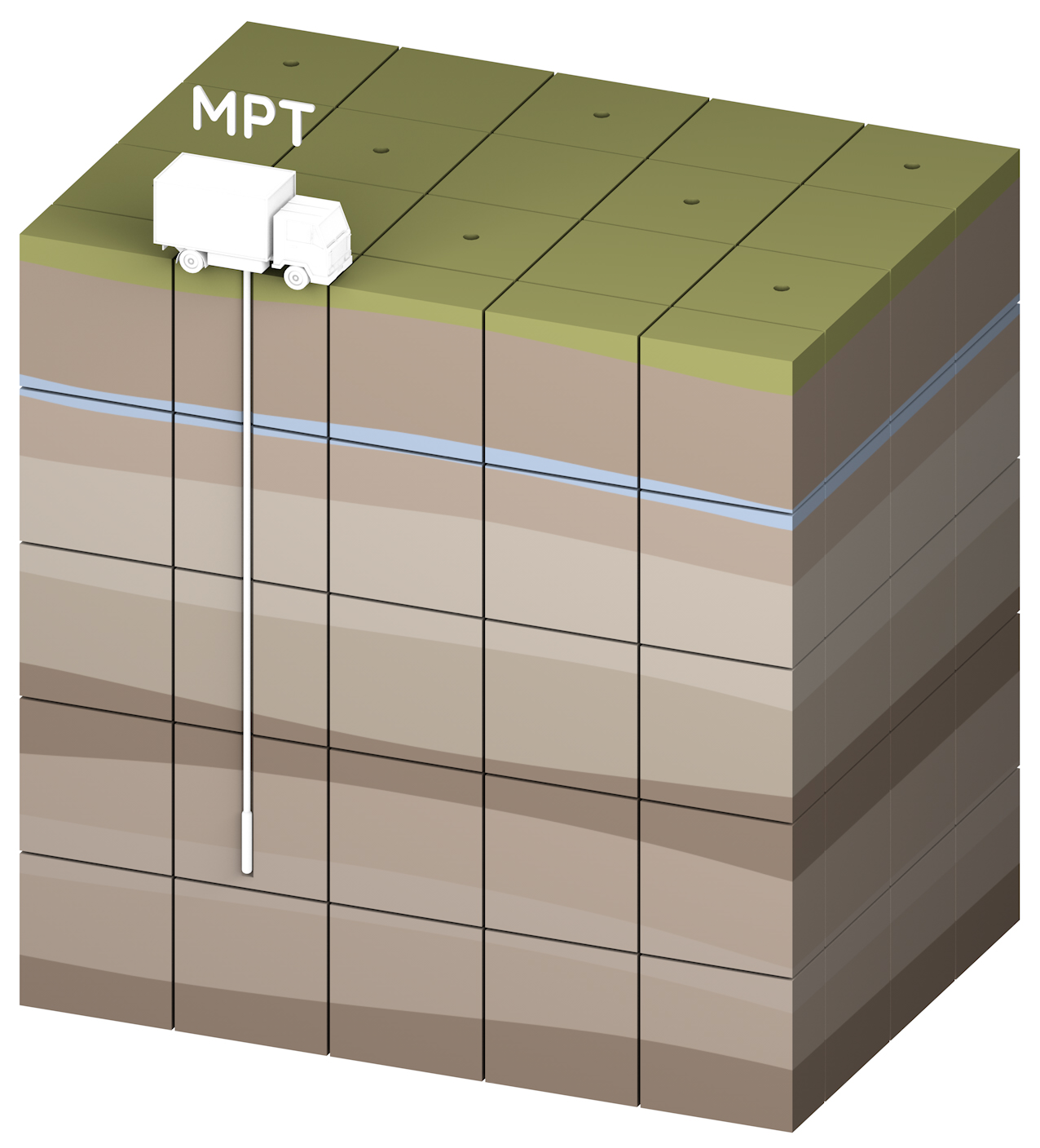

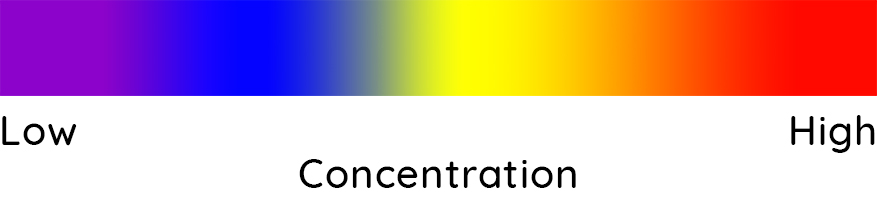

Real time measurement of element concentrations by utilizing our MPT technology. The Metal Probing Tool (MPT) contains an x-ray fluorescence based detector which measures metal concentrations. The detector is build in a small probe which can be advanced into the tailings material by static force. The tool can be combined with Cone Penetration Testing (CPT) and other detectors like Electric Conductivity (EC) for supplementary data.

We can use all kind of equipment for pushing the probe like CPT-trucks and units, Direct Push rigs (Geoprobe) or hydraulically driven stand-alone rigs.

The MPT approach delivers accurate and high resolution data of element concentrations in real time. Compared to traditional drilling and sampling, it is cost-effective and very fast (up to 150 m/day).

For supporting the MPT data, additional tools like the Hydraulic Profiling Tool (HPT) can be applied for getting a better understanding of the hydraulic features of the tailing. The HPT allows for identifying preferential pathways and for evaluating permeabilities.

During this step of investigation, discrete samples will be taken for lab testing and mineralogical analysis. The locations and depth of samples will be chosen based on the MPT data. For collecting samples, small diameter tools based on Direct Push technologies are available.

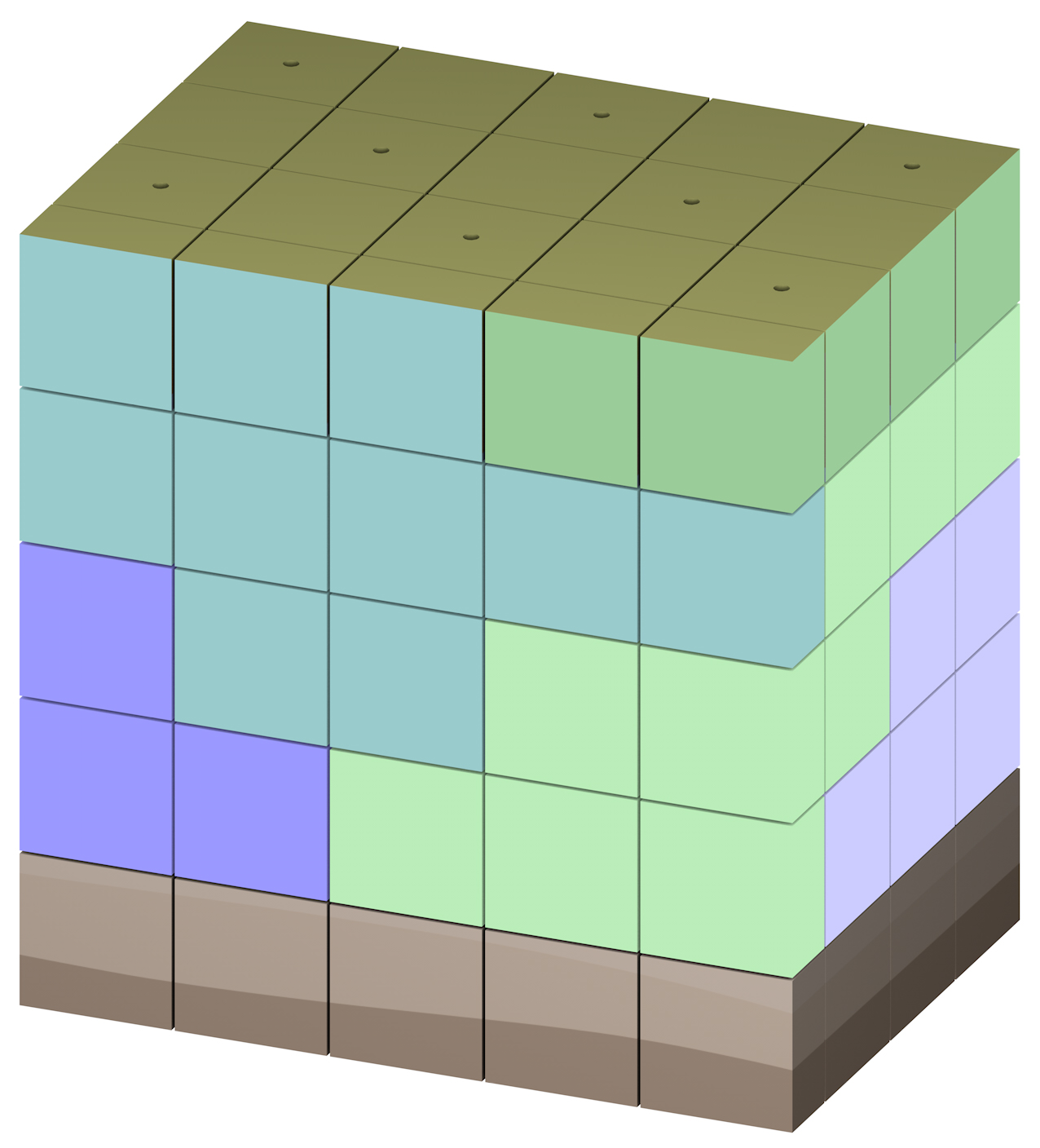

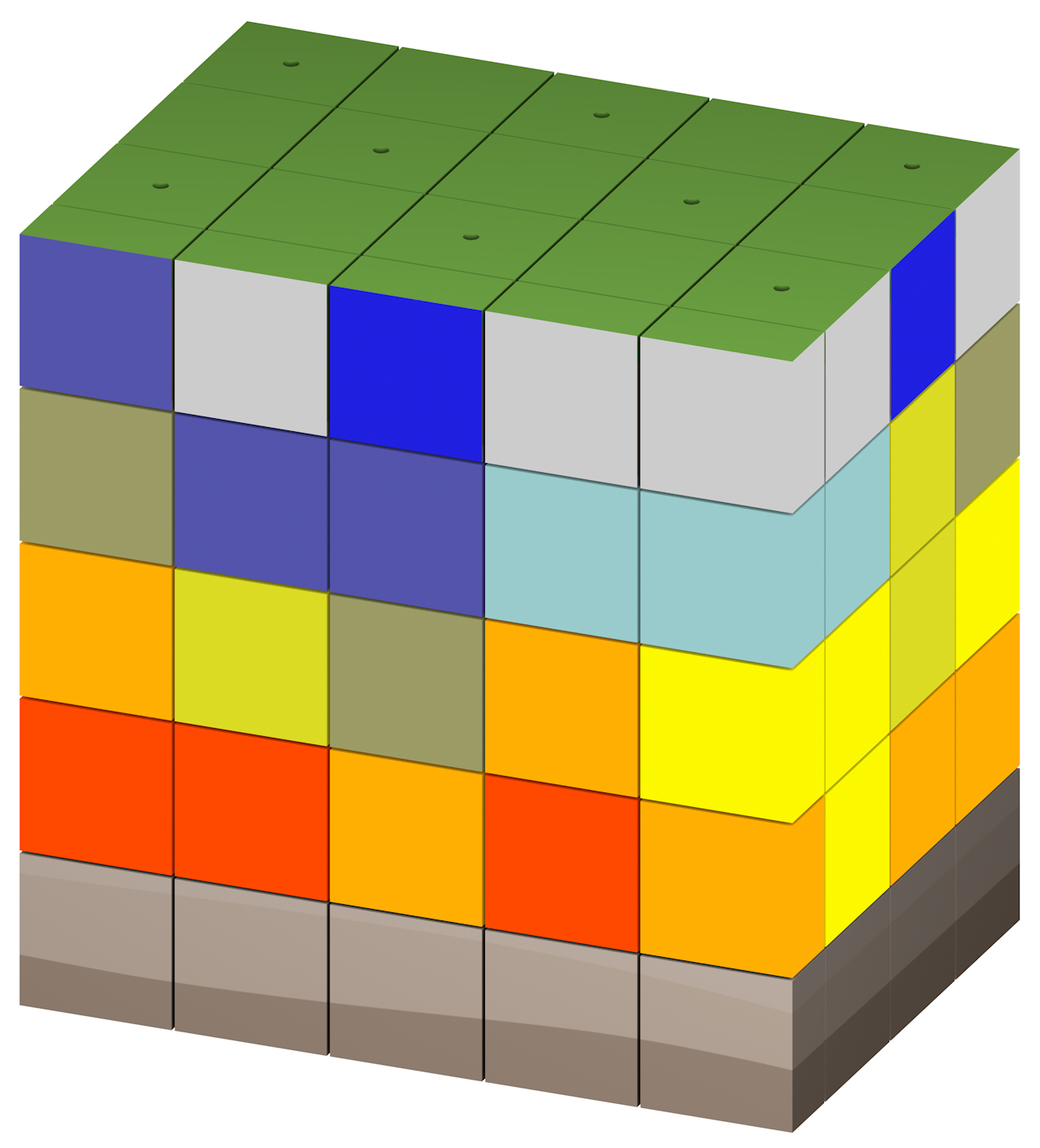

The tailing body will be clustered by differentiation of individual internal structures. Due to the evolution of the tailing body, these are mostly artificial sedimentological patterns.

The clustering is based on:

– CPT soil classification (if applied)

– Mineral composition

– Hydraulic permeability

– Statistic indicators

Individual Clusters

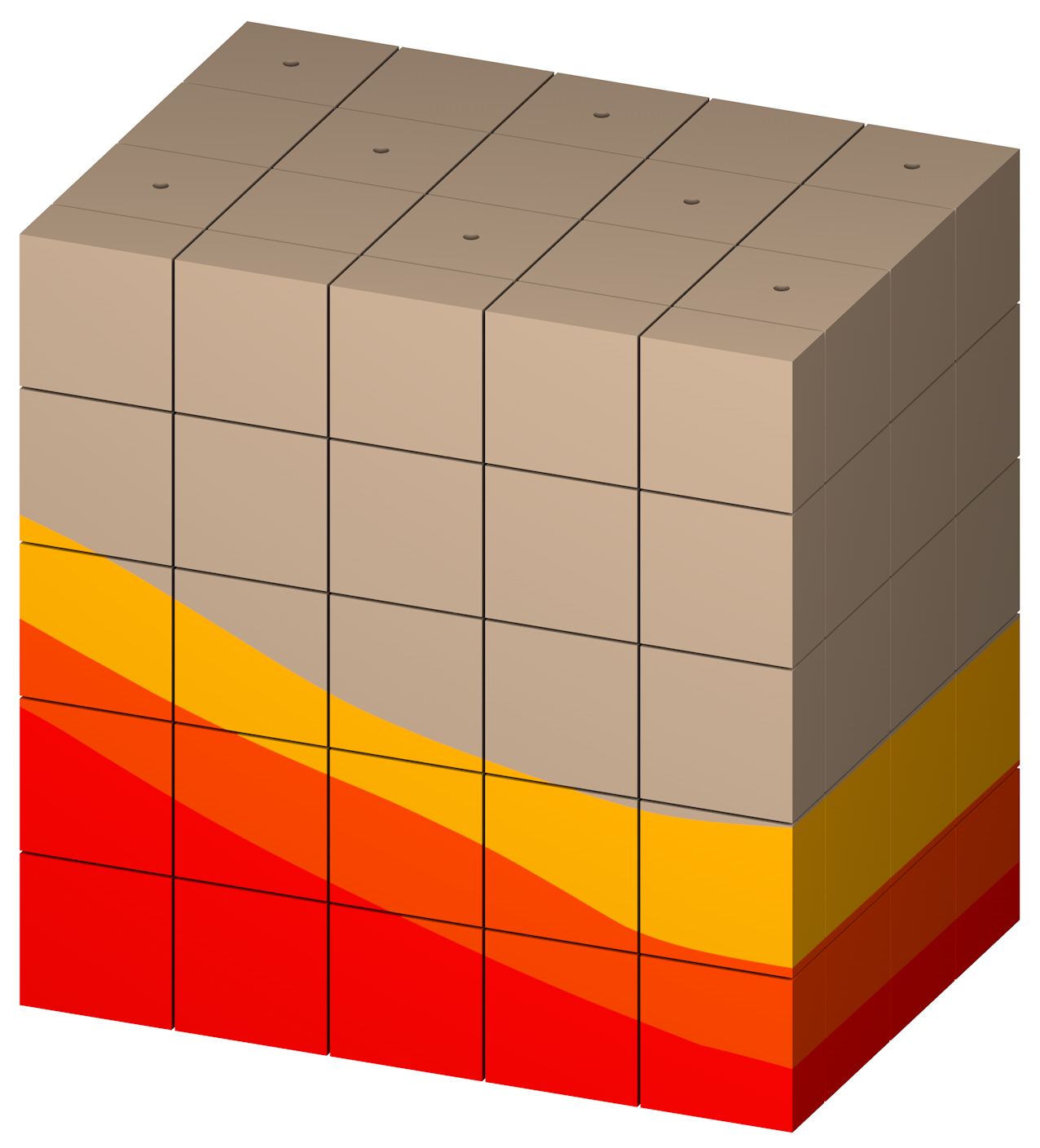

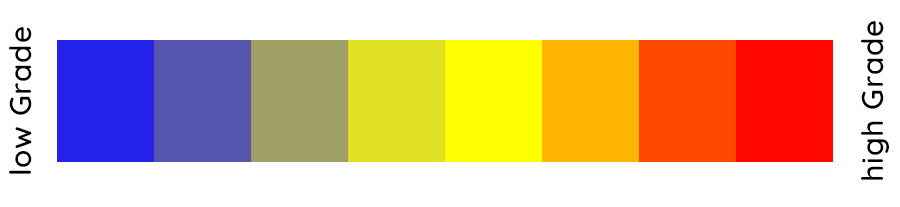

This step includes the geospatial interpolation and modeling. The 3D model is based on segment individual and whole deposit statistics. It allows for identification of zones yielding significant concentrations of metals.

The model considers variography, mineralogy, mineral liberation analysis, element associations and mobility.

Zones of significant and/or ore concentration

This step includes the definition of block-individual ore grades. Non value areas will be delineated by cut-off criteria.

Further steps can involve:

– Clustered Resource Estimation

– Resource Statement according to international Standard(s)

– Assessment of deposit development

– Transformation of resources to reserves

The mining activities of the past centuries all over the world have caused considerable environmental damage. There are risks from the dumps caused by acidification due to pyrite oxidation, the leaching of heavy metals into surface waters and the subsequent contamination of agricultural land.

Soils polluted by harmful elements from mining activities are potential sources of damage for plants, animals, and humans. Immobilization of heavy metals (typically Pb, Zn, As, Cd, Cu) adapted to the environmental conditions of the region interrupts the transfer from soil to crop.

Biotechnological methods can remove and recover the valuable metals remaining in the mineral waste and enable the decontamination of agricultural land affected by emissions from the dumps.

Furthermore, the availability of technologically important, but rarely occurring elements has a high economic relevance. Especially mining dumps are of great relevance for the recovery of strategic elements, as this material – in contrast to primary ore material – has already been processed.

We are a leading organization in cultivation and use of specialized microbes (Acidithiobacillus sp.) for the extraction of valuable metals from mining waste, mine tailings and slags. Our supply chain includes Engineering and construction of bioleaching technologies – equipment, process control and sensor technology.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |